The Heat Miser™

Built For High Temperature Environments

HM180

Gordon’s high-temperature MWD system, HeatMiser™ 180°C, features the same benefits as the GT-MWD but was specifically designed for high-temperature environments up to 356°F (180°C).

HM190X

Gordon’s high-temperature MWD system, HeatMiser™ 190°C EXTREME, features the same benefits of the GT-MWD but was specifically designed for high-temperature environments up to 374°F (190°C).

engineered, built, and proven to solve the problem of MWD tools failing in high-temperature environments over 350°F

Protect Your System

Reduce Failures Relating to High Temperature Wells

The Gordon Technologies Heat Miser MWD system uses advanced technology to save oil companies time and money while operating in the most hostile drilling conditions. It is engineered, built, and proven to solve the problem of MWD tools failing in high-temperature environments. The GT-MWD Heat Miser tool continues to provide the highest performance, efficiency, and reliability in the most extreme drilling conditions.

High Temp. High Performance.

Superior Design Eliminates The Potential For Error

Advanced Mechanical Design

- Innovative module packaging allows a shorter and easier MWD tool to build and service

- Proprietary MWD centralizers and internal shock mounting for improved life of electronic components

Advanced Electrical Design

- Intelligent power management for an optimized battery life

- Four circuit board design reduces the potential points of failure compared to standard eight circuit board systems

- 190°C MWD Electronics and sensor packs are specifically designed for high-temperature environments environments

Real-Time Data Acquisition

- Drilling dynamics; axial and lateral shock and vibration, temperature, RPM for stick-slip measurement

- 6-axis, 6-decimal place raw survey capability for survey management

- High quality data transmission with decoding filter ensuring downhole communication performance

- Optimized data management to utilize fast mud pulse data rates (up to 4 bits per second) for high-speed logging

- Transmits a more detectible signal than any other MWD system

The Gordon Difference

We Do MWD Differently

The Heat Miser, GT-MWD’s high-temperature tool, has an innovative design which enhances the performance of the MWD system while also protecting it from increasingly harsh drilling environments. The combination of the GT-Shock Miser and GT-Pulser is an evolutionary step in MWD technology because it improves the pulse amplitude, enables best-in-class performance in extended laterals, and preserves MWD tool health, increases expected run life, and reduces unplanned trip outs.

Components

Included Features

Shock Miser

Each module in the MWD string contains shock absorption technology which further isolates the electronics from potentially damaging shock and vibration.

Pulser

Led by our patented pulser and transmitter technology, GT-MWD produces larger pulses for strong and reliable detection and is designed to operate in nearly all mud types and drilling conditions.

Surface Decoding

The most technologically advanced and effective signal detection system in the industry allows for reliable decoding of downhole data even in drilling environments with high interference.

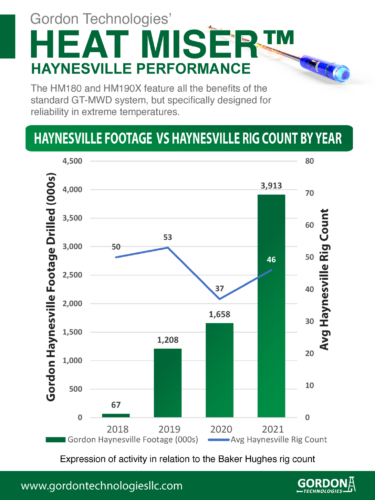

High Temp Fleet

HM180

Gordon’s high-temperature MWD system, HeatMiser™ 180°C, features the same benefits as the GT-MWD but was specifically designed for high-temperature environments up to 356°F (180°C).

HM190X

Gordon’s high-temperature MWD system (HeatMiser™) features the same benefits of the GT-MWD but was specifically designed for high-temperature environments up to 374°F (190°C).

Related Resources

Brochures, Specifications, Case Studies

Customize Your Service

Optional Features And Functionality