Innovation. Performance. Reliability.

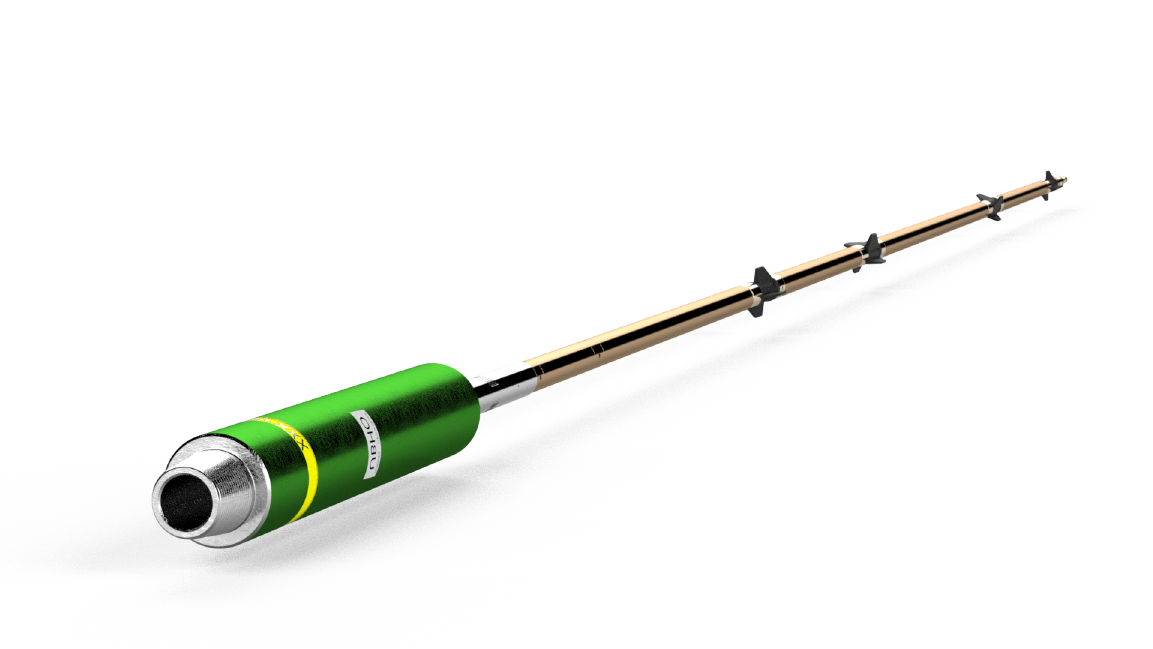

GT-MWD

SHOCK MISER™

GT-Shock Miser is a patented shock and vibration mitigation technology that reduces axial shock from excitation devices by 80%, amplifies the MWD telemetry signal by as much as 300%, filters debris from the mud system and has the highest LCM resistance in the industry.

GT-PULSER

Gordon’s patented pulser allows for faster data rates, longer battery life and industry-leading reliability. It was designed for universal use with all mud systems and features a 200°C temperature capability.

GT-DM

Gordon’s patented Noralis directional module features best in class solid state technology inclusive of fully featured and integrated sensor electronics such as 6-axis, 6 decimal raw surveys with real-time survey corrections.

COMPONENT PACKAGING & CENTRALIZATION

Allows for 50% reduction in number of circuit boards and internal lateral and axial shock isolation and component mounting based on Shock Miser technology. The proprietary exterior centralization fins allow for an extreme wear and corrosion resistant metallurgy design.

DATA COMPRESSION

Gordon’s data compression provides up to 5 bits per second data rates with industry best power efficiency.

DUAL TRANSDUCER DECODING

Noralis Dual Transducer Decoding Systems result in faster data rates at greater depths.

Gordon MWD

The GT-MWD System

Gordon Technologies’ MWD is a faster, more robust, and more reliable MWD system than any other on the market. GT-MWD and GT-Shock Miser were specifically designed to address the most common points of MWD failure in today’s unconventional drilling environments, namely failures due to high temperature and high shock and vibration. The combination of Gordon’s patented pulser and patented shock and vibration mitigation system creates a faster, more robust, and more reliable MWD system that is achieving industry-leading performance.

The Shock Miser™ is the underlying foundation of how we package everything within our tool string

Differentiating Technology

The Gordon Difference

Shock Miser™

GT-Shock Miser is a patented shock and vibration mitigation technology that reduces axial shock from excitation devices by 80%, amplifies the MWD telemetry signal by as much as 300%, filters debris from the mud system and has the highest LCM resistance in the industry.

Directional Module

Gordon’s patented Noralis directional module features best in class solid state technology inclusive of fully featured and integrated sensor electronics such as 6-axis, 6 decimal raw surveys with real-time survey corrections.

Component Packaging

Allows for 50% reduction in number of circuit boards and internal lateral and axial shock isolation and component mounting based on Shock Miser technology. The proprietary exterior centralization fins allow for an extreme wear and corrosion resistant metallurgy design.

Pulser

Gordon’s patented pulser allows for faster data rates, longer battery life and industry-leading reliability. It was designed for universal use with all mud systems and features a 200°C temperature capability.

Data Compression

Gordon’s data compression provides up to 5 bits per second data rates with industry best power efficiency.

Surface Decoding

The most technologically advanced and effective signal detection system in the industry allows for reliable decoding of downhole data even in drilling environments with high interference.

Customize Your Service

Optional Features And Functionality

Heat Miser

TRACKER

GT-AGR

GT-PWD

Unrivaled Surface Capabilities

Rig Site Data Accessible From Anywhere

Digitize Drilling Data

All rig site data is digitized and accessible in one reliable collection point. All the power you need in a single software suite.

App Access

Real-time live stream of rig data through the mobile app, allowing access at any time from anywhere.

Cloud Storage

All current and historical well data is stored on the cloud, enabling historical performance evaluation and new product testing simulations.

Push Notifications

Intelligent surface logic identifies when notable events happen at the rig site and sends SMS notifications to stakeholders.

Automation

Eliminating human error and expediting data delivery and response time through event-triggered reports.

Remote Operations

On-site capabilities are now fully available remotely. Remove a person from a location and reduce your HSE exposure.

Terry Frith, CEO

“In everything we do, we believe in Innovation with Excellence. We believe in thinking differently and thrive on innovating solutions to complex problems”

Chris Lapoint, COO

“We assembled the most knowledgeable industry experts from around the world and came together with a strict focus and common goal… produce the world’s best MWD system.”

Our Customer Stories

Better Service Starts Here

Corporate Headquarters

818 I-10 South Frontage Road, Scott, LA 70583

Phone: +1 337 233 1804

Email: info@gordontechnologiesllc.com

Monday-Friday: 7:00am - 4:30pm

24/7 Support: Contact your local representative

Operational Facility

121 Abigayles Row, Scott, LA 70583

Phone: +1 337 233 1804

Email: info@gordontechnologiesllc.com

Monday-Sunday: Open 24 hours